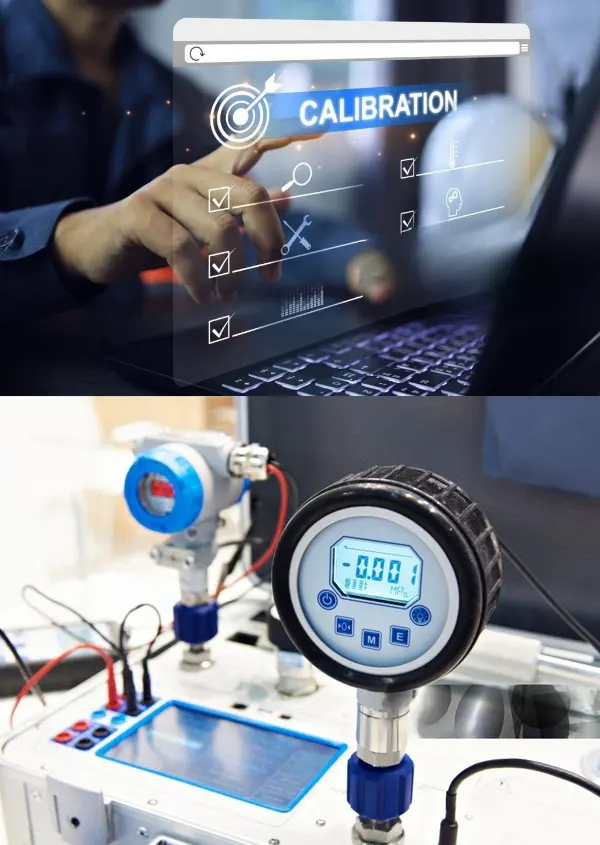

Instrument Calibration

The primary service of MTC is the calibration of measuring instruments such as thermometers, pressure gauges, Temperature cabinet, scales, Universal testing machine, RPM meter and other precision devices (In our scope).

Traceability to National or International Standards

Calibration is typically done using standards traceable to national or international measurement systems (like NIST in India). This ensures that the calibration is credible and meets accepted industry standards.

Certification

After calibration, MTC provide certification, which is an official document verifying that the instrument has been calibrated and meets the required standards. This is often essential for quality control in regulated industries.

Maintenance and Repair

In addition to calibration, MTC also offer maintenance and repair services for measurement devices. Regular maintenance ensures that instruments continue to operate correctly between calibrations.

On-Site Calibration

MTC is offer on-site services, where technicians visit the client's facility to calibrate equipment directly in place, which can be more convenient and cost-effective for large, heavy, or complex instruments.

Industry-Specific Services

Different industries require specialized calibration services. MTC cater to sectors like manufacturing, pharmaceuticals, automotive, aerospace, food safety, and energy, offering services tailored to each field's specific standards and regulatory requirements.

Accuracy

Ensures measurement precision, which is crucial for quality control, research, and development.

Compliance

Many industries require that instruments be calibrated to meet regulatory or quality standards (e.g., ISO, FDA, etc.).

Reliability

Many industries require that instruments be calibrated to meet regulatory or quality standards (e.g., ISO, FDA, etc.).